When you think of powder, what comes to mind? The average person can think of flour, laundry detergent, etc.

Today I'm going to talk about titanium powder. What is titanium powder?

Titanium powder is also hidden in our daily life. For example: the festival, we see fireworks, colorful bloom, the main material of the colorful is titanium powder. Of course, this is only one of the least noteworthy uses.

Titanium powder (hydrogenated) is a black-gray irregular powder.

Uses: Titanium powder and titanium hydride powder is a very widely used metal powder. Powder metallurgy, alloy material additive. At the same time, it is also an important raw material such as cermet, surface coating agent, aluminum alloy additive, electric vacuum getter, spray and plating. Also used in aerospace, spraying, metallurgy, fireworks and other industries.

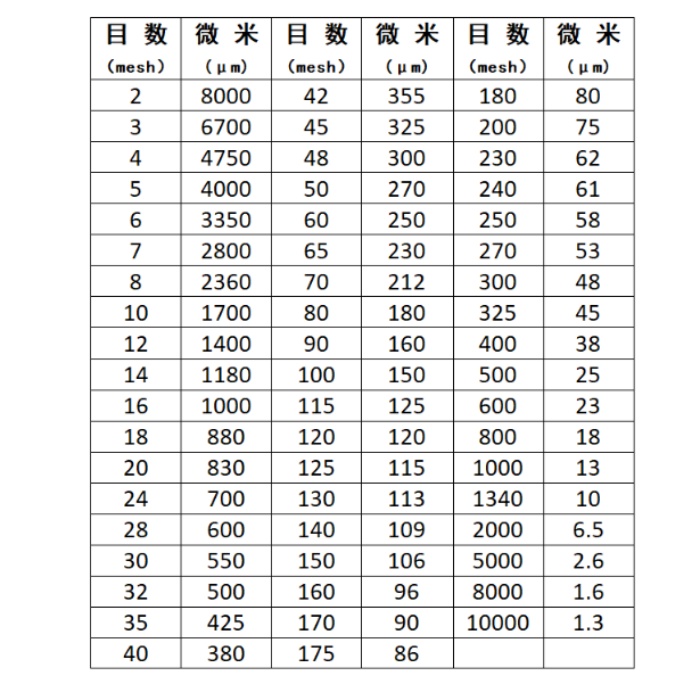

The main parameters are: particle size (mesh number), titanium content, hydrogen content, vibration density, etc.

Properties of titanium powder:

1. Chemical composition

Mainly refers to the content of titanium metal and the content of impurity components, the higher the content of titanium in titanium powder, the lower the impurity content is, the higher the purity of titanium powder, the higher the grade. High-quality titanium powder is often the lowest oxygen content, so the advantages and disadvantages of titanium powder are often dependent on the oxygen content in it

2. Physical properties

Titanium powder is more active than titanium metal, easier to react with other elements or compounds, easier to oxidize, flammable, explosive, and belongs to dangerous goods. Therefore, titanium powder packaging has special requirements. When packaging titanium powder, vacuum packaging must be used, the outer packaging uses inert gas argon protection, and the outer packaging uses explosion-proof drums.

The manufacture of titanium powder

There are many methods to produce titanium powder, mainly mechanical alloying, hydrogenation dehydrogenation (HDH), atomization, metal thermal reduction and molten salt electrolysis.

At present, the most popular method in China is hydrogenation dehydrogenation (HDH). Hydrogenation dehydrogenation is a process for preparing titanium powder by using the reversible property of titanium and hydrogen. The HDH method is to use titanium sponge after hydrogen absorption to produce brittleness, easy to be mechanically crushed, to make titanium hydride powder, and then under vacuum conditions of high temperature dehydrogenation to produce pure titanium powder.

1 Using a horizontal hydrogenation furnace, hydrogenation reaction occurs when the temperature is raised above 350℃ under positive pressure of hydrogen, and then the temperature reaction begins to be intense, and a large number of hydrogen absorption, hydrogen holding for 3h, and then slowly cooling to room temperature in the hydrogen atmosphere, titanium hydride powder with a hydrogen content of 3.8%±0.2% can be obtained.

2 Ball milling is carried out under the protection of protective gas, which can effectively avoid the contamination of titanium powder and also avoid the occurrence of titanium hydride naturally to ensure the safety of production.

3 Titanium hydride of different particle sizes can be obtained by ball milling. The ground titanium hydride is put into the furnace for dehydrogenation reaction. Under vacuum conditions, the temperature rises to more than 680℃, and the titanium hydride quickly decomposes hydrogen. The whole dehydrogenation process maintains a low vacuum degree and lasts for about 19h, and the titanium powder is finally obtained.

4. Titanium powder of different particle sizes is classified by different mesh screens (screening systems).