Titanium powder is a key raw material for manufacturing high-performance aviation structural components. Its excellent biocompatibility in medicine is mainly applied in the manufacture of personalized implants. Titanium powder is one of the core raw materials in metal 3D printing.

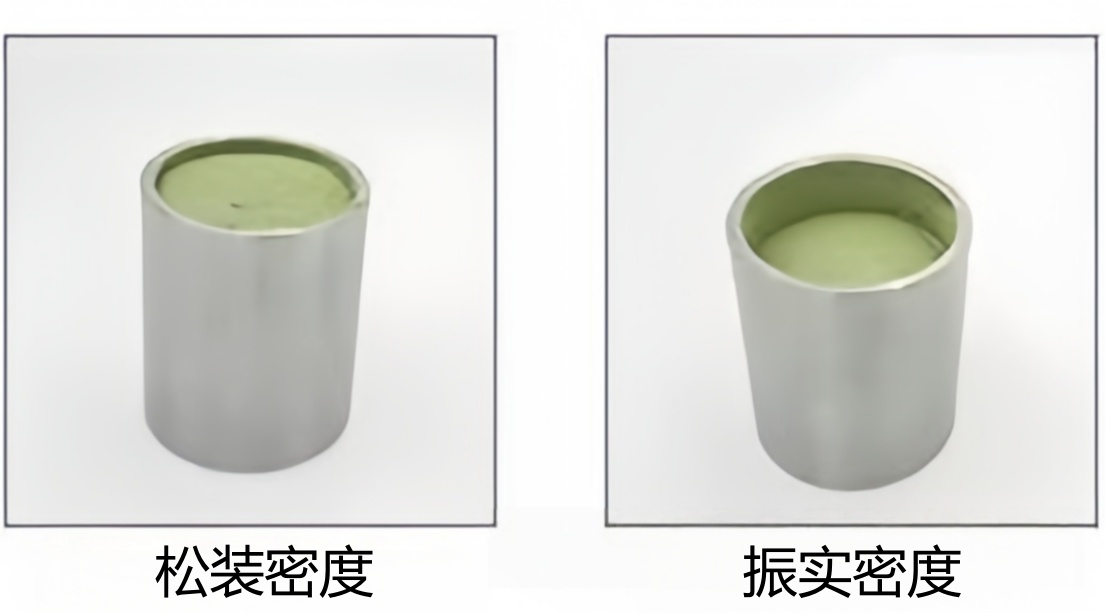

The density of titanium powder is interrelated with its mesh size. The density of titanium powder refers to the mass of titanium powder per unit volume. In practical applications, the density of titanium powder can be divided into loose density and tap density.

1. Loose density: Reflects the natural accumulation ability of powder, affecting the uniformity and fluidity of powder spreading.

2. Tap density: refers to the ultimate packing density of powder formed after vibration in a container under specified conditions. It is a macroscopic manifestation of physical parameters such as particle size, morphology, and surface characteristics. A higher value indicates better powder fluidity.

How to measure the tap density of titanium powder?

1. Sample pretreatment: Titanium powder needs to be dried at 100℃ for 0.5 hours to eliminate moisture interference.

2. Vibration setting: Adjust the amplitude and frequency according to the type of material.

3. Data collection: Weigh three times and take the average (three measurements are taken by the same measurer).

The tap density of titanium powder is not a fixed value, and it can vary significantly due to factors such as powder preparation process, particle size distribution, sphericity, and oxygen content.

1. Spherical titanium powder: tap density 2.7–3.0 g/cm³. Usage: commonly used in advanced manufacturing processes such as 3D printing and metal injection molding.

2. Irregular titanium powder: tap density 2.7–3.3 g/cm³. Usage: As a core raw material for powder metallurgy, irregular titanium powder can be processed into titanium and titanium alloy components through processes such as pressing and sintering.

The density of titanium powder is an important factor affecting the mixing process of titanium powder.

1. Under the same conditions, the smaller the density difference between titanium powders of different particle sizes, the easier it is to mix them evenly. This is because during the mixing process, titanium powder particles of different mesh sizes do not easily exhibit weight segregation during movement.

2. Under the same conditions, the greater the density difference between titanium powders of different particle sizes, the harder it is to mix them evenly. This is because during the mixing process, titanium powder particles of different mesh sizes exhibit a tendency to sink when the density is higher, and light titanium powder particles tend to float upward, making it difficult to achieve even mixing.

Titanium powder is widely used in multiple fields due to its unique physical and chemical properties. It plays an irreplaceable role especially in aerospace, medical implants, and 3D printing. Therefore, we should pay more attention to key parameters and strive for excellence to produce higher-quality products.