Gas tungsten arc welding (English: GTAW welding, abbreviated as GTAW) or tungsten inert gas welding (English: TIG welding) is an arc welding method that uses a non-melting tungsten electrode for welding.

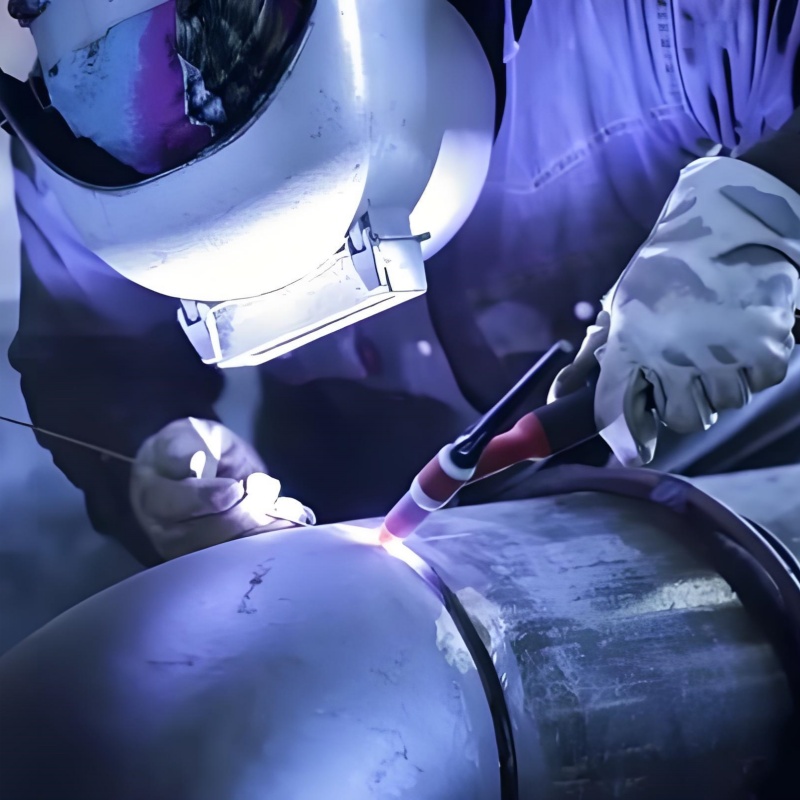

During GTAW welding, the welding area is protected from atmospheric pollution by shielding gas (such as inert gases like argon), and usually a filler metal (welding filler metal) is used in combination. However, some self-filling weld seams can omit this step. During welding, the electric arc, which conducts through highly ionized gas (i.e., plasma) and metal vapor, acts as a constant current welding power supply to provide energy. It is a welding method that uses a tungsten electrode as a non-melting electrode, operates under the protection of an inert gas (usually argon Ar or helium He), and forms a weld seam by melting the base metal and the filler wire (if used) through the arc generated between the tungsten electrode and the workpiece. In simple terms, it is like using an "unmelting match" (tungsten electrode) to generate a high-temperature flame (electric arc), while using a "protective gas" (inert gas) to blow away the surrounding air, preventing metal oxidation and nitriding, and achieving precise and high-quality welding.

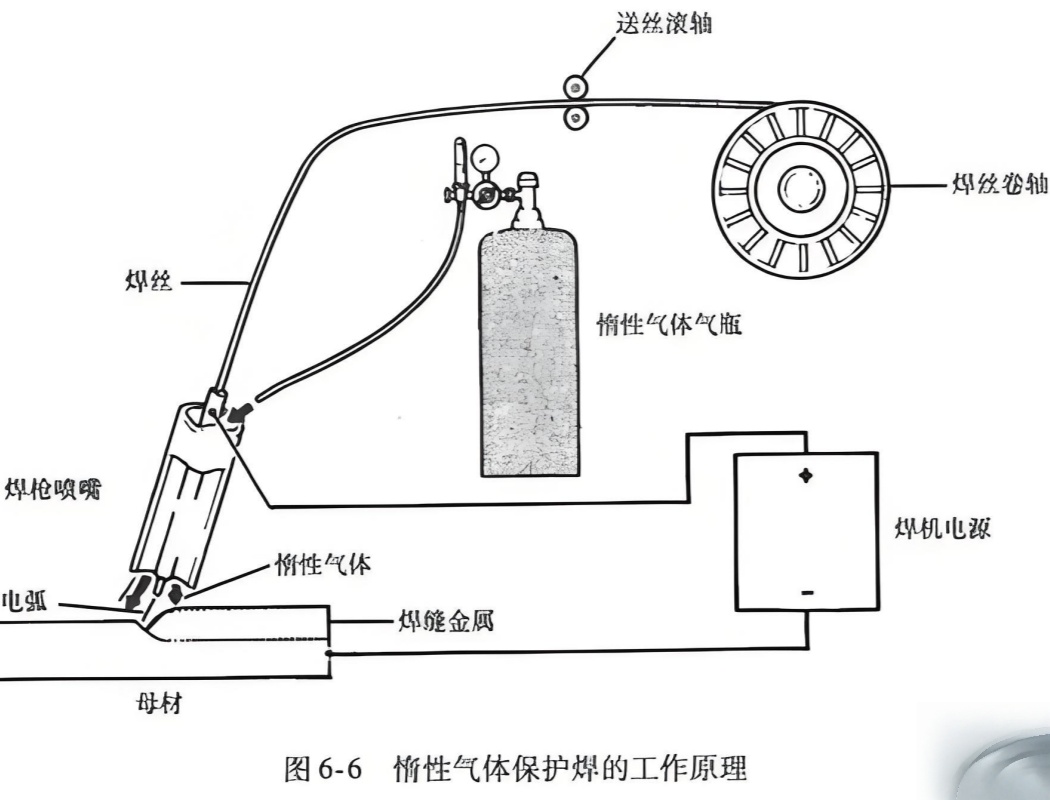

The working principle of tungsten inert gas protection welding

1. Arc ignition: A high-frequency high voltage or short-circuit contact is applied between the tungsten electrode (negative electrode) and the workpiece (positive electrode) to ignite the electric arc.

2. Formation of the molten pool: The electric arc generates extremely high temperatures (up to over 6000°C), rapidly melting the welding area of the workpiece, forming a liquid molten pool.

3. Gas protection: The inert gas continuously sprayed from the nozzle of the welding gun evenly covers the arc, the molten pool, and the already solidified but still at high temperature weld seam, isolating it from harmful gases in the air such as oxygen and nitrogen, preventing metal oxidation and nitriding, and ensuring the purity and mechanical properties of the weld seam.

4. Filler metal: If filler metal is needed (such as for welding thick plates or requiring reinforcement of the weld seam), the welder will use the other hand to insert the filler wire into the front of the molten pool. The wire is melted by the electric arc and then fused with the base metal.

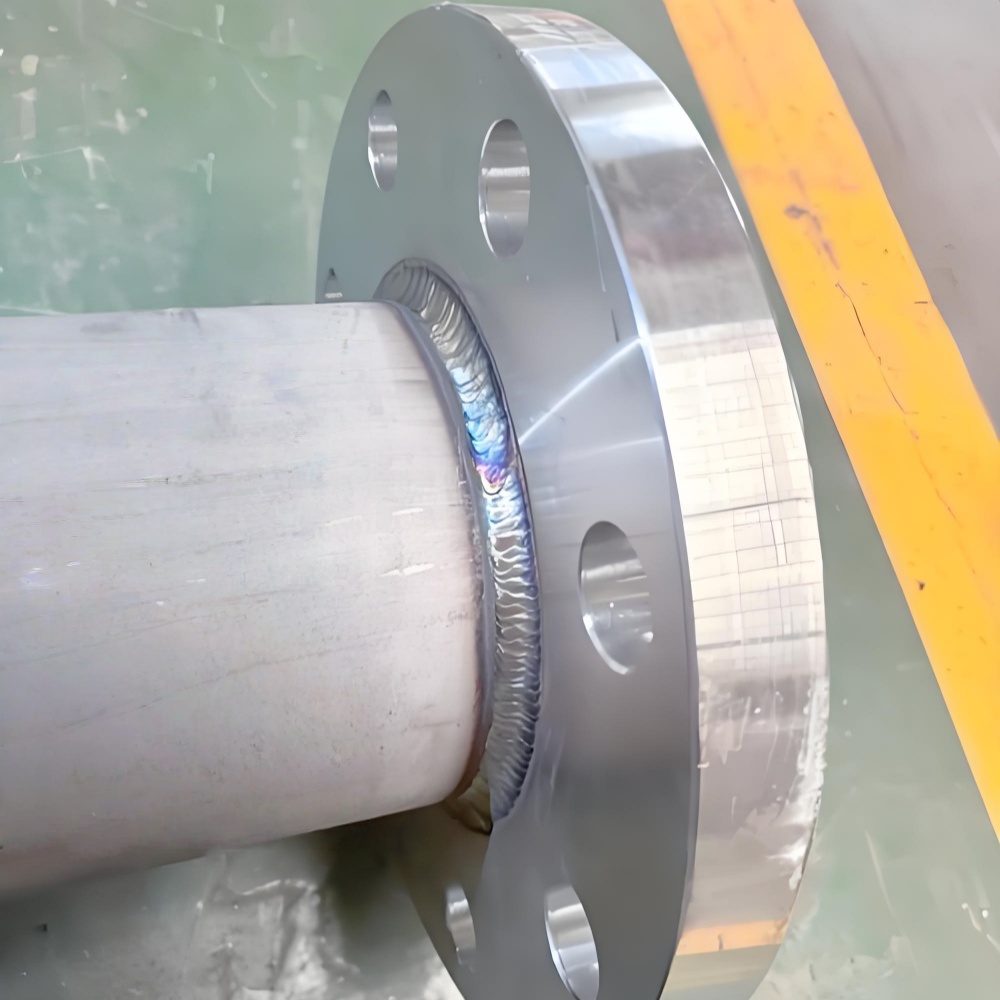

5. Cooling and crystallization: As the electric arc moves, the liquid metal at the rear of the molten pool gradually cools and crystallizes, ultimately forming a continuous and dense weld seam.

The equipment of tungsten inert gas protection welding mainly includes the following parts: 1. Welding power supply: Provides the energy required for welding. TIG welding usually uses a direct current power supply or an alternating current power supply.

2. Direct current positive connection: The tungsten electrode is connected to the negative pole, and the workpiece is connected to the positive pole. This is the most commonly used connection method. The arc is stable, the tungsten electrode can carry a large current, and the penetration depth is large. It is suitable for welding most metals, such as carbon steel, stainless steel, copper, titanium, etc.

3. Welding gun: It is a tool held by the welder, and it is equipped with: tungsten electrode: the core component, serving as the electrode, requiring a high melting point (3422℃) and high conductivity. Commonly used types include pure tungsten, cerium tungsten, lanthanum tungsten, zirconium tungsten, and thorium tungsten (due to radioactivity, they have been gradually phased out).

4. Nozzle: Made of ceramic or metal, used to guide the shielding gas, ensuring its uniform coverage of the welding area.

5. Electrode holder: Used to hold and fix the tungsten electrode.

6. Gas supply system: Gas cylinder: Stores inert gas, the most commonly used is argon, as it provides stable arcs and low cost. Helium or argon-helium mixed gas is used in situations requiring higher heat input (such as welding thick titanium plates or aluminum plates).

7. Pressure reducing valve/flow meter: Reduces the high-pressure gas in the cylinder to the working pressure and precisely controls the gas flow (usually 8-15 L/min).

8. Cooling system: Air cooling: Cools the welding gun by relying on natural air flow, suitable for intermittent welding with low current (generally below 150A).

9. Water cooling: Cools the welding gun through a circulating cooling water (usually deionized water) for high current, long-term continuous welding situations, ensuring the welding gun does not overheat.

Tungsten inert gas shielded welding is widely used in industries where the quality of weld seams is extremely demanding: 1. Aerospace: Welding of key components such as aircraft engine parts, fuselage structural components, rocket fuel tanks, etc. for aerospace titanium products.

2. Titanium and titanium alloy pressure vessels and pipelines: Used for base welding in scenarios where "zero leakage" is required, such as nuclear power plant pipelines, chemical equipment, food and pharmaceutical-grade pipelines, boilers, etc.

3. Food and pharmaceutical industries: Used for tanks, pipelines and equipment with extremely high requirements for weld surface smoothness and corrosion resistance.

4. Welding of electrode blocks during titanium ingot production.

Precautions for tungsten inert gas shielded welding. 1. Tungsten materials are difficult to dissolve. During work, strict control must be implemented to prevent the formation of difficult-to-dissolve inclusions during electrode welding.

2. Arc radiation protection: A light-transmitting welding mask must be worn to prevent the eyes and skin from being burned by intense ultraviolet and infrared rays (such as arc eye disease and skin peeling). Wear long-sleeved flame-retardant welding suits, leather gloves and safety shoes.

3. Electrical safety: Check if the equipment grounding is good. Avoid operating in humid environments to prevent electric shock.

4. Harmful gas protection: When welding in poorly ventilated spaces (such as enclosed containers), the inert gas will displace the air, which may lead to suffocation. Local ventilation devices or air-supplying respirators must be used.

Tungsten inert gas shielded welding is a high-quality, high-precision and high-demand welding method. It is known as "welding art" and is one of the ultimate tests for welders' skills, as well as an indispensable key connection technology in the titanium and titanium alloy industry.