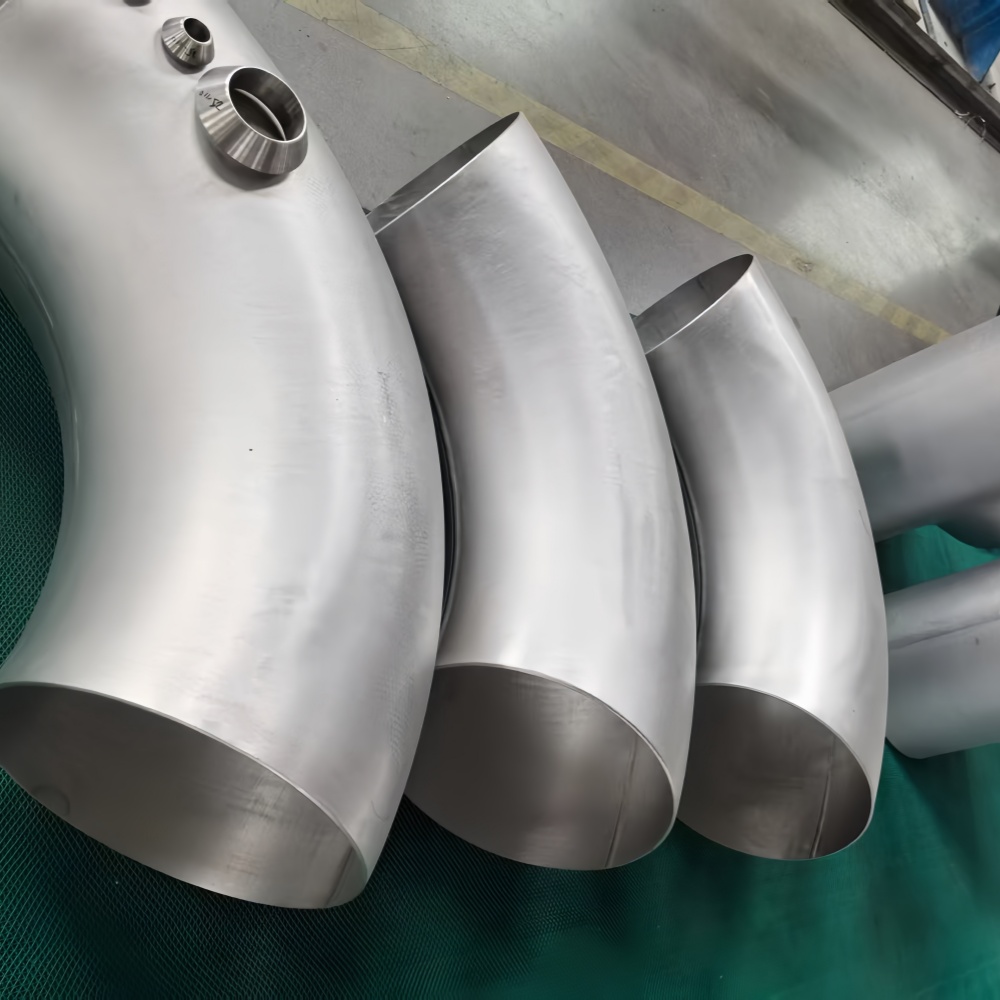

Titanium and titanium alloys are widely used in the manufacturing of reaction vessels for strong acids and strong alkalis due to their excellent resistance to chemical corrosion. To remove rust and oxide scale from the surface of parts, improve surface roughness, and enhance mechanical properties, shot blasting technology has been introduced into the surface treatment of titanium alloys.

Shot blasting is a widely adopted surface strengthening process that uses steel shot to bombard the surface of workpieces and implant residual compressive stress, thereby enhancing the fatigue strength of the workpiece and beautifying the surface of the product through cold working.

Shot blasting utilizes a shot blasting machine's high-speed rotating impeller to accelerate shot (typically steel shot) and throw it at the surface of the workpiece. Through the impact and friction between the shot and the workpiece surface, impurities such as oxide scale, rust, and welding slag are removed from the surface of the workpiece, while a certain compressive stress is induced on the surface of the workpiece to improve its fatigue strength.

Shot blasting equipment typically consists of a shot blasting machine, shot circulation system, workpiece conveying system, and dust removal system. The main consumable for shot blasting machines is steel shot.

Steel shot is a spherical particle made from special materials through special heat treatment. First, high-quality steel blocks and steel shavings are melted, and then the molten steel is thrown into water using a high-speed centrifugal disk to rapidly cool the surface temperature and form shot. The shot is then sorted through mechanical sieves into different grades that meet SAE standards for use in shot blasting equipment.

The size of steel shot is classified by its diameter, such as 10#, 12#, 16#, 20#, etc. The diameters of these grades of steel shot are 0.3mm, 0.5mm, 1.0mm, 1.2mm, 1.6mm, and 2.0mm, respectively. Additionally, steel shot of different diameters can be customized according to specific application requirements. The hardness of steel shot is generally HRC58-62.

In the daily shot blasting processing of titanium and titanium alloys, time, pressure, speed, and angle are important process parameters.

Time refers to the duration that the workpiece is subjected to shot blasting in the shot blasting machine.

Pressure refers to the pressure at which the shot blasting machine sprays the shot material.

Speed refers to the speed at which the shot material is projected onto the surface of the workpiece.

Angle refers to the spray angle of the shot material from the shot blasting machine.

The selection of parameters for the shot blasting process has a significant impact on the processing effect and quality of the workpiece. In actual product processing and shot blasting applications, the optimal parameter combination is achieved through batch trials based on the material, shape, surface condition, and processing requirements of the workpiece.

As an important surface treatment process in the titanium and titanium alloy industry, shot blasting has extended its application to high-precision fields such as aerospace. With its advantages of efficient and simple surface treatment, shot blasting has a wide range of applications in various industries. With the development of technology, shot blasting will play an even greater role in the processing of titanium and titanium alloys.