In the processing and application of titanium fasteners, the consistency and uniformity of the products, as well as the dimensional accuracy of the parts, directly determine the quality and performance of the finished products. How can we ensure the interchangeability of titanium fasteners and control the tolerance of key dimensions? The Go/No-Go Gauge is an excellent gatekeeper. Despite its seemingly simple structure, it is an efficient, reliable, and economical quality control tool.

What exactly is a Go/No-Go Gauge? It is a type of gauge. In actual production, if a large number of products are measured one by one using measuring tools (such as vernier calipers, micrometers, etc., which have scales), it is very time-consuming. Qualified products have a certain measurement range, and those within this range are qualified. Therefore, people use Go gauges and No-Go gauges for measurement.

Still confused? Let's imagine a scene where a sieve is being used to sift sand. The sand on top of the sieve is not suitable, while the sand below is qualified.

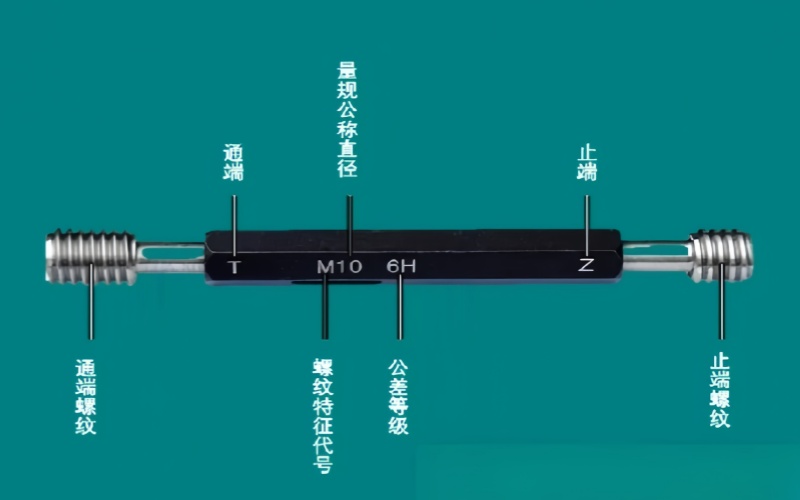

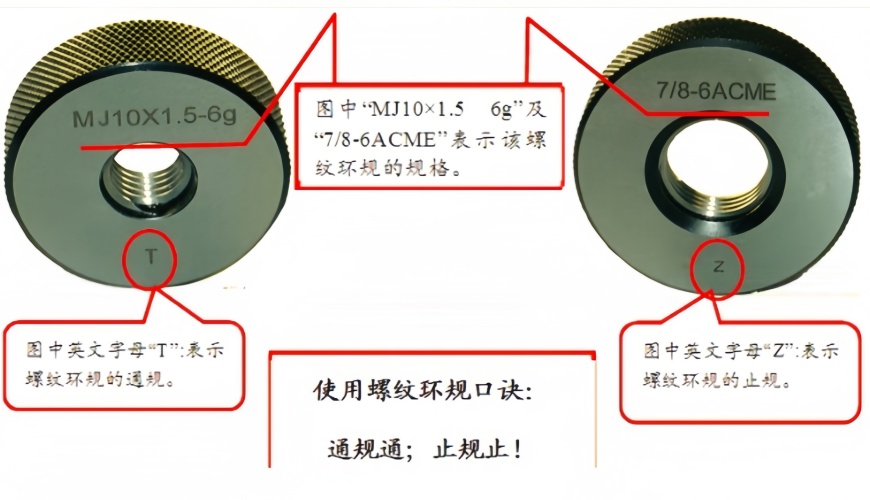

In fact, Go/No-Go Gauges are divided into two parts:

Go Gauge: It is used to detect the maximum material dimension of the part. If the Go gauge can pass through the part smoothly, it indicates that the part's dimension has not exceeded the upper limit of the tolerance.

No-Go Gauge: It is used to detect the minimum material dimension of the part. If the No-Go gauge cannot pass through the part, it indicates that the part's dimension has not fallen below the lower limit of the tolerance.

Go/No-Go Gauges can generally be divided into two types:

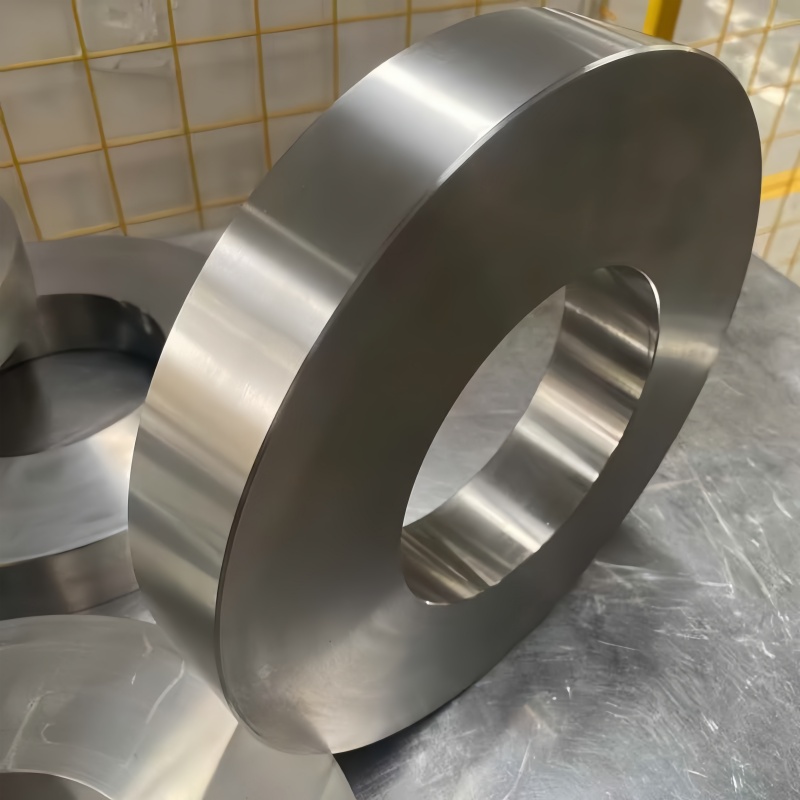

Smooth Plug Gauges/Ring Gauges: They are used to measure the diameter of cylindrical holes (plug gauges) or cylindrical shafts (ring gauges). They are the most basic and widely used type.

Thread Plug Gauges/Ring Gauges: They are used to measure internal threads (plug gauges) or external threads (ring gauges). The Go end checks the minimum material dimension of the pitch diameter and root diameter (or crest diameter) of the thread to ensure the thread can be screwed together; the No-Go end checks the single pitch diameter of the thread to prevent it from being too tight.

Correct usage and precautions for Go/No-Go Gauges:

1. Cleanliness first. Before and after use, the working surfaces of the gauges and the surfaces of the parts to be measured must be cleaned. Any dirt, chips, or burrs can lead to misjudgment.

2. Gentle operation.

Go end: Let it pass through (hole) or fit into (shaft) only by the weight of the gauge itself or with slight thumb pressure. Do not forcefully strike, press, or rotate!

No-Go end: Apply slight force to confirm that it cannot pass through or only allows a very small amount to enter (as specified by the standard).

3. After use, clean thoroughly, apply anti-rust oil, and store in a dedicated box to avoid bumps, drops, rust, and mixing.

The simple design, clear judgment, low cost, and efficient detection speed of Go/No-Go Gauges have made them the foundation of titanium fastener production and processing. With the clear signals of "pass" and "fail", they guard the bottom line of each key dimension, ensuring that titanium fasteners can be precisely assembled together during assembly. Understanding its principle, mastering its correct usage method, and attaching importance to maintenance and care are essential skills for every titanium professional and a key tool for ensuring stable and reliable product quality.